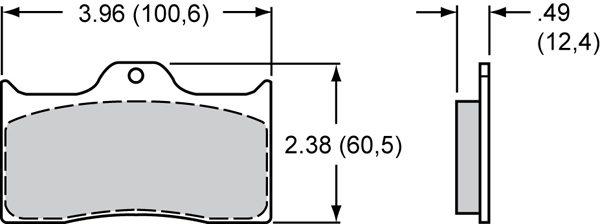

15E-6096K - Wilwood Drag Street Performance Pads: Pad# 7112

15E-6096K

SAME DAY SHIPPING (if ordered before 2pm EST)

These Replacement Pads would be for the various Wilwood Drag Brakes Moser Engineering offers

Sold in sets of 4.

$100.00

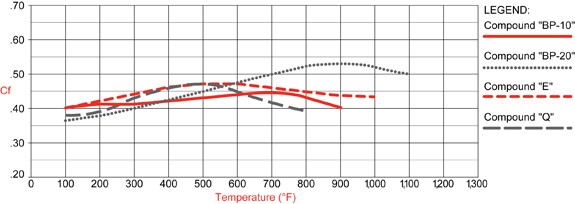

Wilwood PolyMatrix E Replacement Brake Pads

| Wilwood Compatible Calipers: Pad # 7112 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||